1000+ Happy Customers

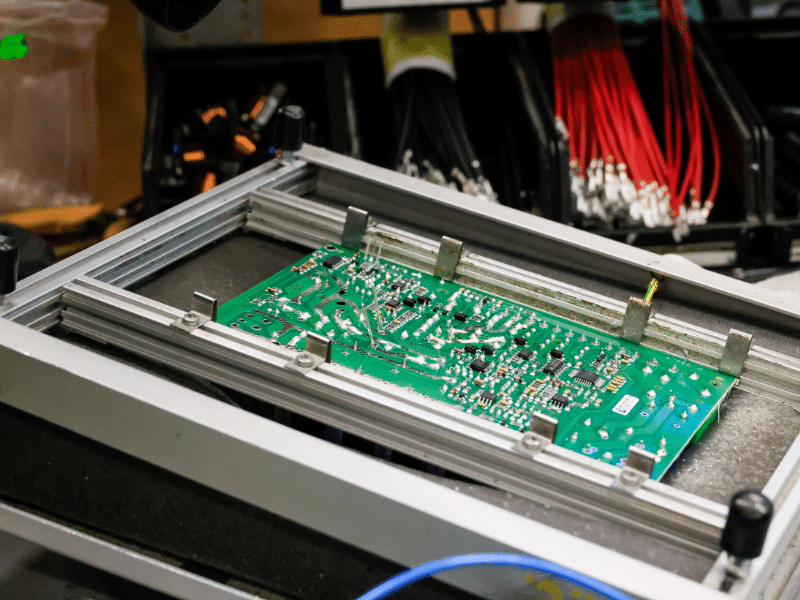

Electronics manufacturing

EMS Services

At MERAWEX we take responsibility for the entire process!

As a long-standing manufacturer of our own electronic products, we know that only working with a reliable partner guarantees the delivery of a customised product.

Our experienced team can help you right from the design stage. We complete the necessary components and then assemble the product in accordance with the documentation. We can then program the whole thing and install it in the housing. Finally, we inspect the finished device and arrange delivery to our customer.

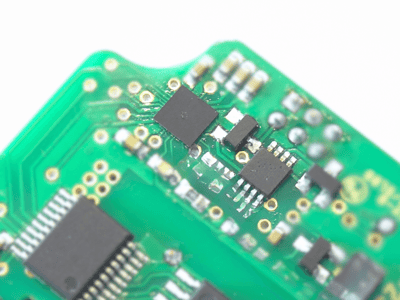

Our electronic assembly services are aimed at companies wishing to commission small and medium-sized series of their devices. We offer both automatic assembly of SMD and through-hole components as well as fabrication and assembly of mechanical components. As we are constantly working with proven component suppliers, we can also supply the components needed for production. Companies that want to check the correctness of their design can take advantage of the support of our engineers and perform EMC tests in our EMC test chamber. We can also program the assembled product and test its operation according to the customer's specifications.

SMT surface mounting

THT through-hole assembly

Electronics design

Ordering electronic components and PCBs

Assembly of customer and own components

Prototyping and testing

AOI 3D Control

Traceability

Delivery to the end customer

SMT assembly

is completed by an automatic 3D optical inspection. This ensures that 100% of assembled circuits are inspected for correct assembly.

THT through-hole assembly

It is carried out by hand, on a wave or with a selective soldering robot, depending on customer preference and product specifications. All electronics assembly is carried out in the ESD zone using the IPC 610.

Machine park of the SMD line

Benefits of working with us

Experience

MERAWEX continually strives to optimise production costs by investing in technological development and the improvement of production processes.Thanks to its modern machinery and experienced staffthe company provides high quality services and a professional approachto customer needs.

Quality

Because we also manufacture our products we understand what is important for companies supplying an electronic device. We are aware that quality means both correct and timely assembly.

Flexibility

We are familiar with the entire production process from conception and design to the launch of the final product. Therefore, we are not limited to the assembly of electronic components. We can carry out testing and research, make the mechanical components, organise the procurement of components and dispatch the final products.

MERAWEX has implemented and applies an integrated ISO 9001 quality

and ISO 14001 environmental management system.

The Factory Production Control System is continuously supervised and regularly audited by CNBOP-PIB, VdS and DNV certification bodies.

In the field of electronics assembly, we apply the IPC 610 standard.

Przykładowa realizacja

Case study

Klient zwrócił się do nas z problemem niedziałających czujników nacisku.

Podjęto kroki:

- analiza otrzymanego elementu będącego źródłem problemu

- przeprowadzenie badań z użyciem promieni rentgenowskich

- zlokalizowanie problemu leżącego po stronie źle zamontowanego komponentu BGA

- zamówienie i montaż programowalnego kondycjonera rezystancyjnego z 36 wyjściami

- odesłanie do klienta

Would you like to find out more?

We are familiar with electronics manufacturingand EMS services and would be happy to share our experience with you.